Team Members

Theodore Andrzejczyk, Zoe Estberg, Roldan Isern-Toledo, Mihir Rao, Nicholas Butcher, Bo Gehrke, Griffin Martin, Hailey Rohlfing, G Davis, Daniel Guisandes, Jacob Nicholas, Rashad Stubbs

Abstract

Our group was tasked with improving the set-up process of the ultra-lightweight camouflage net systems, ULCANS. Currently it takes 1.5-man hours to set up the camouflage. To do this our group made major improvements in two areas of the process which were the deployment stage and the camouflage shape dispersion stage. To improve the deployment process, our group made a roller for the clients to roll the camouflage on and a large U-shaped collapsible moment arm that attaches to a pivot on the ground to swing the camouflage over the vehicle. To decrease the input force required by the soldiers to rotate the large U-shaped collapsible moment arm a pulley system that attaches to two poles on the base plate was added. With this system our group predicted that with two soldiers the deployment time would be cut down to just under ten minutes. To improve the camouflage shape dispersion, process our group made a bipod attachment for the current collapsible poles that the army has which allows them to stand up by themselves. This improvement was made after talking with soldiers who set the camouflage netting up complaining about this part being the most annoying in the process. All these improvements come in at a cost of under $815 which Is 19% under budget.

Pitch Video

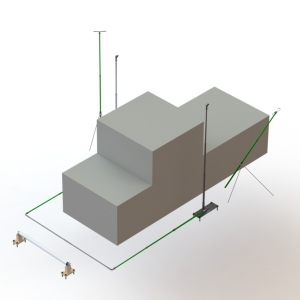

3D Interactive Product Model

The following is an interactive 3D model of the product design. You can view and rotate the product assembly in different orientations and views, including an exploded view to see the various parts that make up the assembly.