Team Members

Adrian Acosta Santos, Vincent Furey, William Jorgensen, Ryan Rinzel, Paul Campbell Samuel Gonzalez, Ryan McKinney, Jarred Simmons, Dane Dickerson, Addison Haskew, Shayne Pollock, Dylan Warren

Abstract

The team’s goal when designing our concept was to make the deployment and retraction of the camo netting faster and easier. We noted in the current process that the biggest difficulties with the netting were getting it on top of the truck and having to drag it off in order to fold it. We felt that these were the main difficulties faced when dealing with the camo netting, pushing us to focus our design around solving them. To solve the issue of having to maneuver the large netting bundle to the top of the truck, we designed a storage compartment that can be attached to the top of the vehicle in varying ways. By storing the net on top of the truck, a significant amount of time is saved in the deployment process as a soldier doesn’t need to struggle to lift it on top of the truck. This storage system also gave us a structure to place our retraction method in. Using paracord and a hand crank, we developed a way for the netting to be retracted back into the storage system. By weaving the paracord through the daisy chain, the netting folds like an accordion when being cranked back towards the storage box. This allows for the netting to be collected and stored without having to drag off the truck as well as deployed quickly. By introducing a single storage system with a crank and reel implemented into it, the process of deploying and collecting vehicle camo is significantly easier and faster; allowing a single soldier to do both in under 3 minutes.

Pitch Video

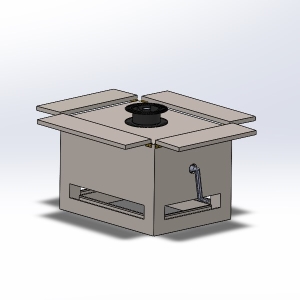

3D Interactive Product Model

The following is an interactive 3D model of the product design. You can view and rotate the product assembly in different orientations and views, including an exploded view to see the various parts that make up the assembly.