Team Members

Sofia Cruzan, David Dickerson, Alex Gonzalez, Maxwell Haar, Joseph Harmon, Joshua McHarris, Matthew Nguyen

Abstract

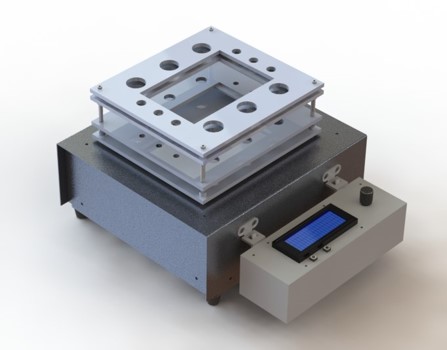

Our shaker table includes low-cost materials with an intuitive user-interface design to satisfy the requirements of the UF Biofoundry with advanced software and electrical implementation. The passion motivating our group is the ability to facilitate scientific breakthroughs for the UF Biofoundry by providing them with an optimal and effective product in their research. Using a belt-driven system powered by two stepper motors, our shaker table meets the necessary linear, orbital, and double orbital movements with all the additional size, weight, heat, duration, and OD/FI requirements. The LCD screen user interface includes a rotary encoder and two buttons to allow the user a simple and straightforward process when implementing functions (duration, speed, radius, and pattern) into the shaker table. The enclosure for the motors and OD/FI electrical, and the control box for the electrical components both ensure that the shaker table will be IP-X5 certified. The enclosure is made of two parts to allow for easy removal to access the motors and other inner components. Several parts, including the control box and well plate, were manufactured using 3D printing, which allowed for fast prototyping and low cost. The OD/FI system consists of an array of UV and visible light LEDs along with a photoresistor to measure the optical density and fluorescence intensity of the specimens. Overall, our design was able to effectively meet the customer needs in a unique and optimal manner.

Pitch Video

3D Interactive Product Model

The following is an interactive 3D model of the product design. You can view and rotate the product assembly in different orientations and views, including an exploded view to see the various parts that make up the assembly.