Team Members

Eduardo Artiles, Anthony Beougher, Joel Cruz, Drew Fernandez, Jason Hackett, Andrew Kaye, Cara Pamintuan, Daniel Rodrigues de Souza

Abstract

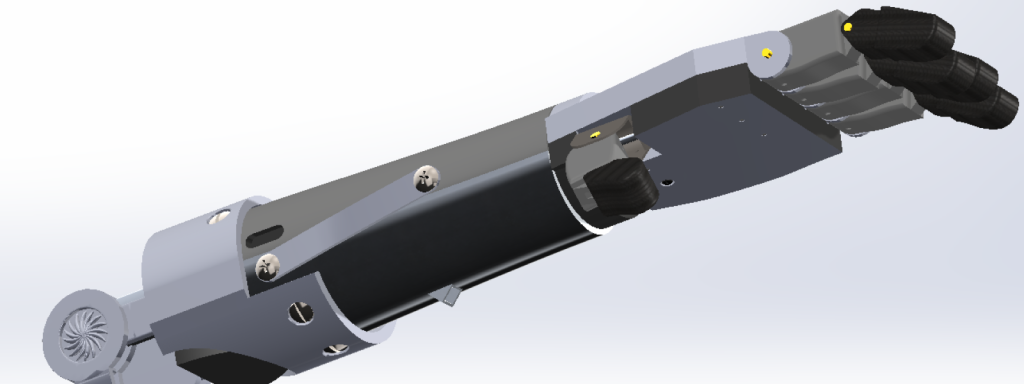

Approximately two million people currently suffer from limb loss, with about 185,000 additional amputations occurring each year. The feasibility of robot prosthetics is anticipated to increase with technological advancements in artificial intelligence and 3D printing. The main problems that prosthetics currently face are the unreasonable cost and complexity for the user, especially in the growing markets outside of North America. Our product, known as “gAIn-A-Grip”, aims to provide an affordable and intuitive design to adults with an above elbow amputation. To create an affordable product, the foundation of our prosthetic arm and hand design is 3D printed. Off-the-shelf parts are also used wherever possible. The most significant feature of the design is that the arm uses computer vision and artificial intelligence to detect and identify objects. A real-vision camera looks out of the palm and an infrared distance sensor looks out of the wrist. An AI algorithm was trained to detect some common household items and set one of five corresponding grips accordingly. The grip automatically initiates once it is close enough to the object and stops once the actuators sense resistance. The algorithm runs on an Arduino Mega microcontroller. For objects outside of the AI database, manual buttons can be pressed to set a grip. A button is also used to release the grip once the user is done. Linear actuators and wire tendons are used to close the fingers. To maximize comfort, the socket that attaches to the residual limb has padding and an adjustable strap. To provide grip in lifting objects, each finger is outfitted with a silicone covering. The prosthetic’s two batteries must be charged each night, but the arm uses a simple USB-C connection and can sit on a separate mount for convenience.

Pitch Video

3D Interactive Product Model

The following is an interactive 3D model of the product design. You can view and rotate the product assembly in different orientations and views, including an exploded view to see the various parts that make up the assembly.