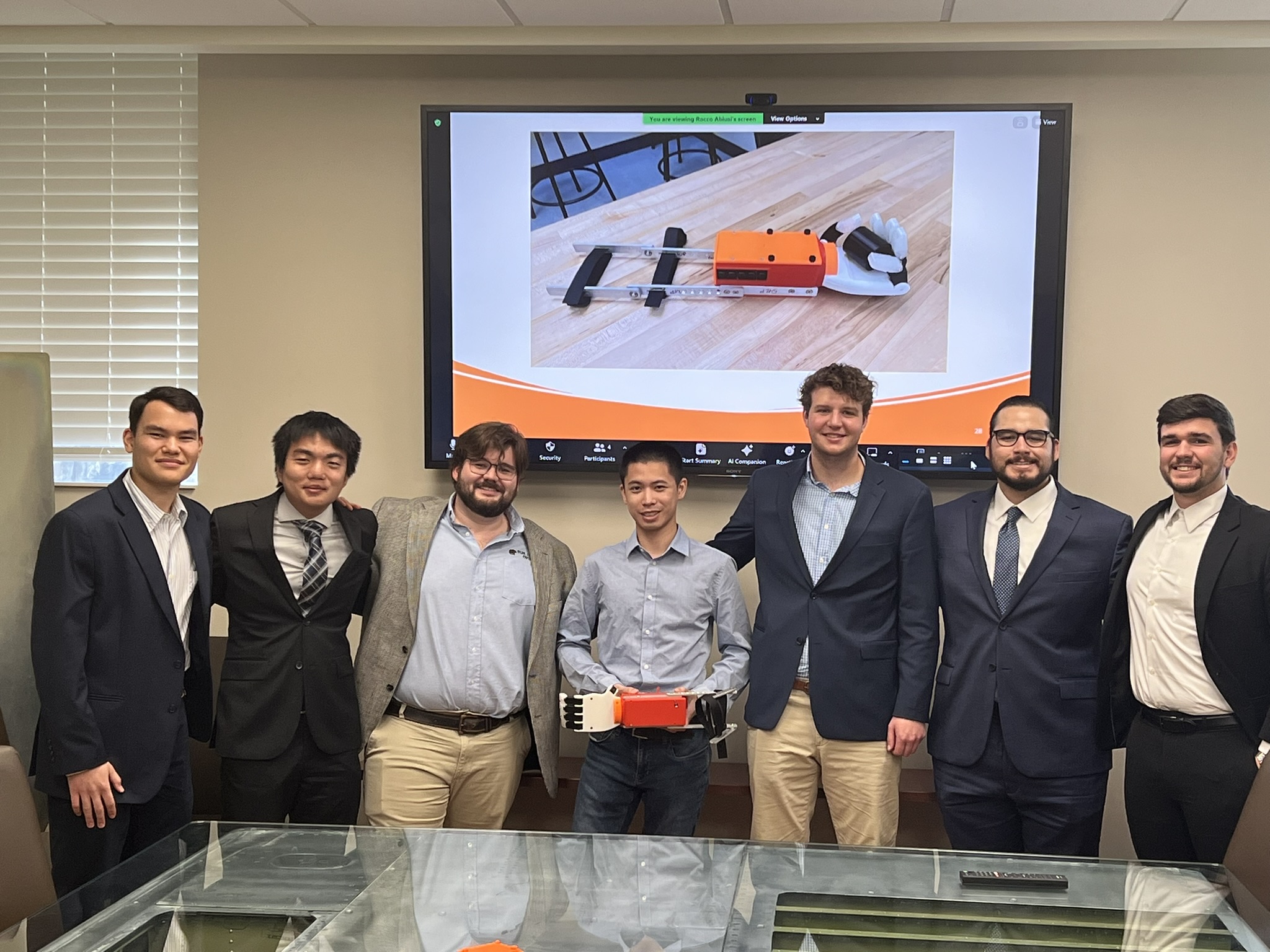

Team Members

Brian Barfield, Rocco Abiusi, Bo Gehrke, Tsz Pan Chu, Jett Su, Tyler Gray, Ethan Ott

Abstract

All over the globe men, women, and children are living with only one hand to carry out their daily lives. These people live without a prosthetic which makes performing everyday functions more difficult. This is an issue, not because the technology does not exist, but because most people in developing countries do not have access to this technology. Functioning prosthetic arms can costanywhere from $10,000 to $50,000, which is simply out of the question for many of the people who desperately need it, especially those living in developing countries. CyberLimb Technologies prosthetic arm aims to be the cheapest, most manufacturable and the most accessible prosthetic arm on the market. With a simple set of Allen keys and a few basic tools our prosthetic can be assembled in these developing regions, by users, caretakers, and humanitarian groups. Most parts of the hand can be printed so humanitarian groups can purchase the CAD model, print their parts, pair them with a kit having the rest of the parts, and then they can fully assemble these arms and distribute them to those who need them. With much of the manufacturing and assembly completed by the consumer, manufacturing costs are very low, and the total price of the arm will be thousands of dollars less than cosmetic non-functioning prosthetic arms currently on the market. Adjustable arm straps on the prosthetic allow it to fit a range of people and be able to adjust to the needs of the user.

Pitch Video

3D Interactive Product Model

The following is an interactive 3D model of the product design. You can view and rotate the product assembly in different orientations and views, including an exploded view to see the various parts that make up the assembly.