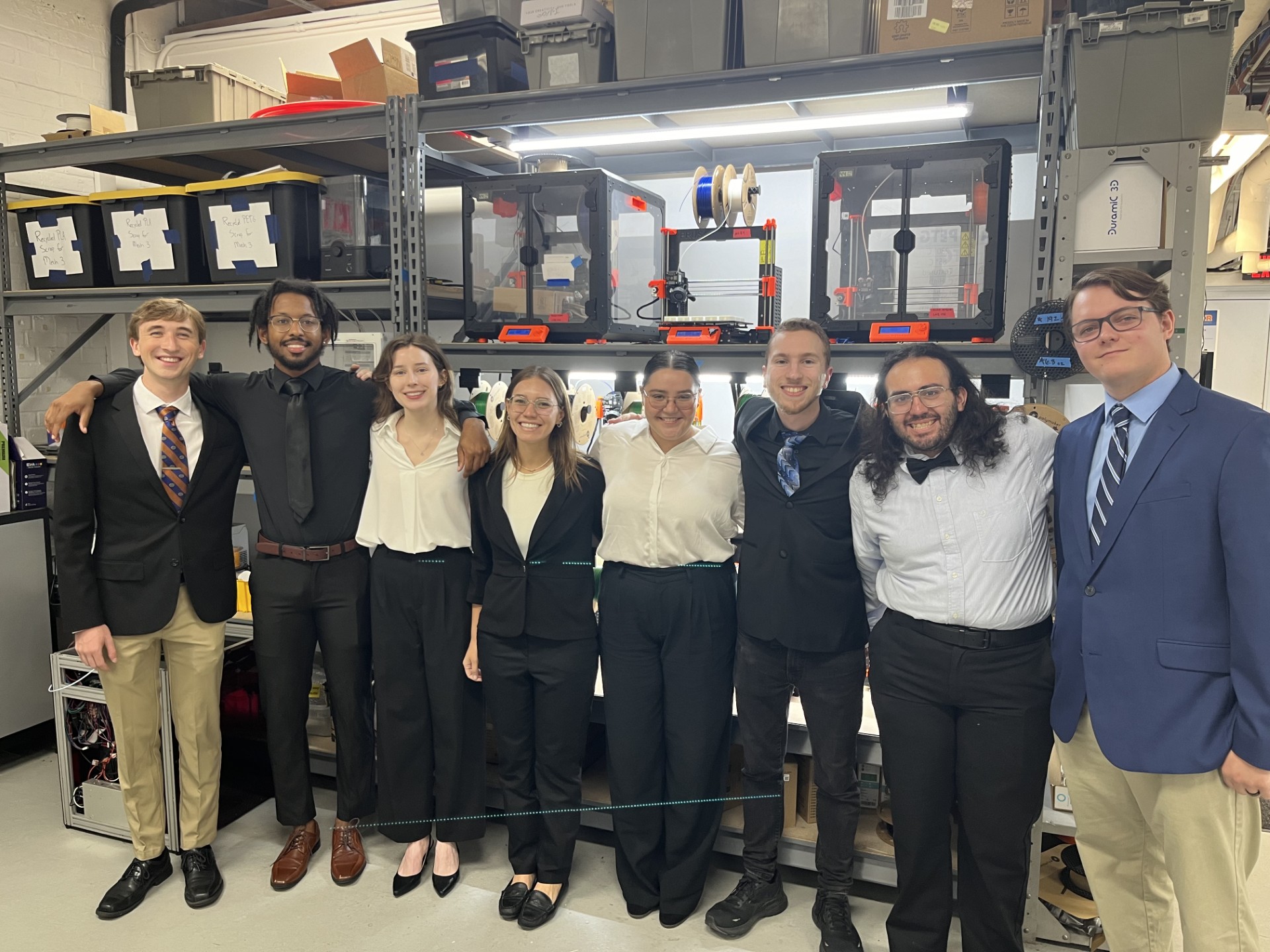

Team Members

Chase Eskridge, Christopher Lopez, Christopher Lopez, Gabriel Gilvary, Isabella Camacho, Julia Gallo, Nathan Berner, Nathan Berner, Osaji Skyers, & Sophia Sayre

Abstract

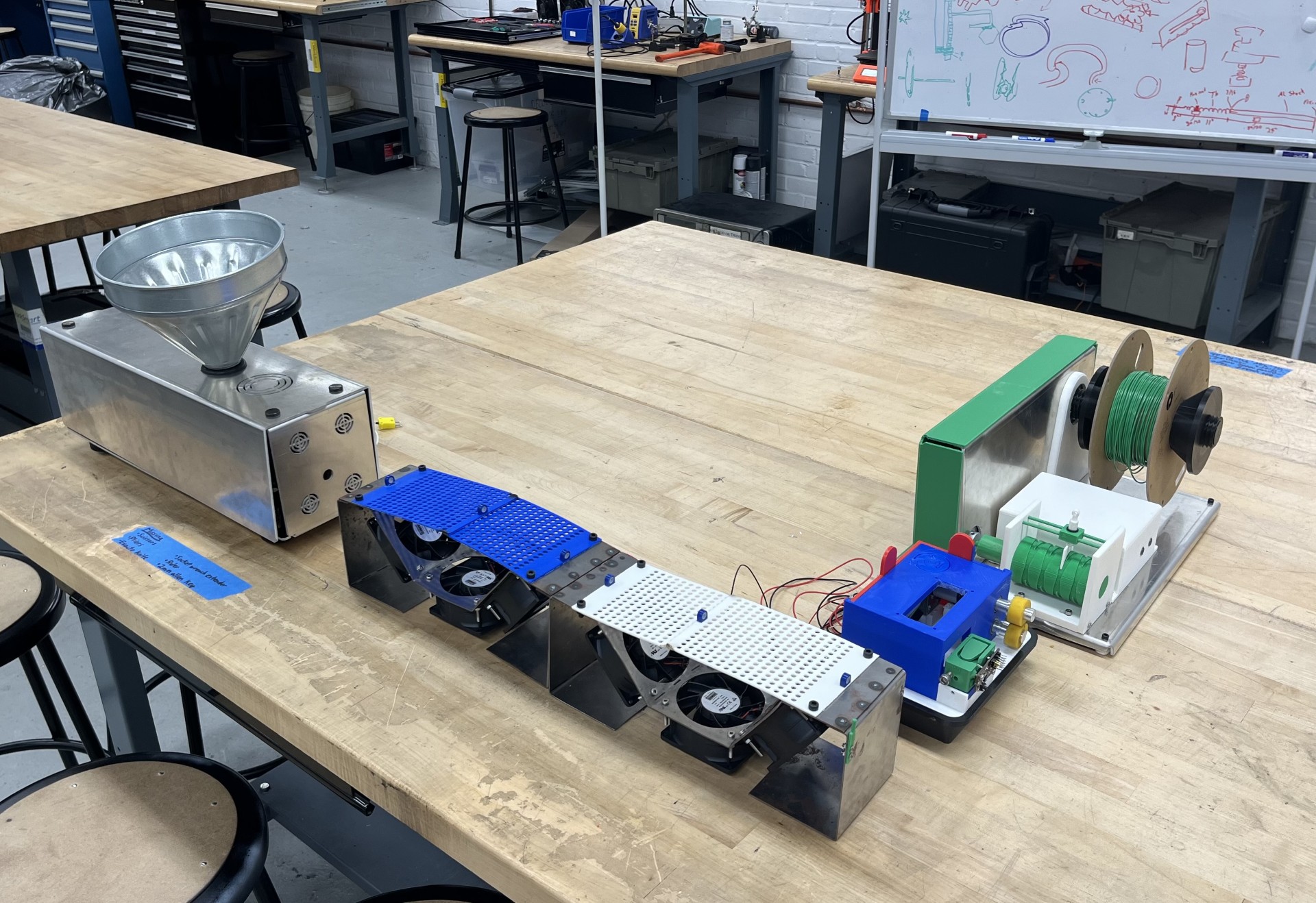

Additive manufacturing processes (e.g. 3D printing), while generating less waste than subtractive manufacturing, still produce enough debris to be considered environmentally harmful since this material cannot be recycled through normal means. This waste has been characterized as ‘3D Printer Poop’ in the popular media, branding additive manufacturers as serious polluters. To minimize 3D-printed waste, ReXtrude™ designed its 3D Filament Recycler! Current filament recyclers are expensive and slow. In response, ReXtrude™ created its fast, high quality, and affordable 3D Filament Recycler. In addition to being more economical than all our competitors, our recycler saves customers money by converting waste into reusable filament. First, the recycler reprocesses 3D print waste through its extruder subsystem. The material emerges as new, hot filament, which is fed through a cooling and real-time diameter sensing zone. ReXtrude™ leveraged expertise of non-Newtonian flow, thermal-fluids, mechanical design, and controls to produce the world’s fastest tabletop filament extruder with the most accurate cooling zone & diameter control system. The cooled filament is wound onto a spool for easy filament use on any standard 3D printer. No more waiting for Amazon to deliver that 3D printer filament! Customers can make their own filament instantly while building their reputation as eco-friendly 3D printing companies in addition to saving money and reducing waste.

Pitch Video

3D Interactive Product Model

The following is an interactive 3D model of the product design. You can view and rotate the product assembly in different orientations and views, including an exploded view to see the various parts that make up the assembly.