Team Members

Jonah Schulman, Konrad Gilbert, Lorant Domokos, Lucca Propst Szwako, Michael Gold, Ricardo Martinez, Stephanie Norman

Abstract

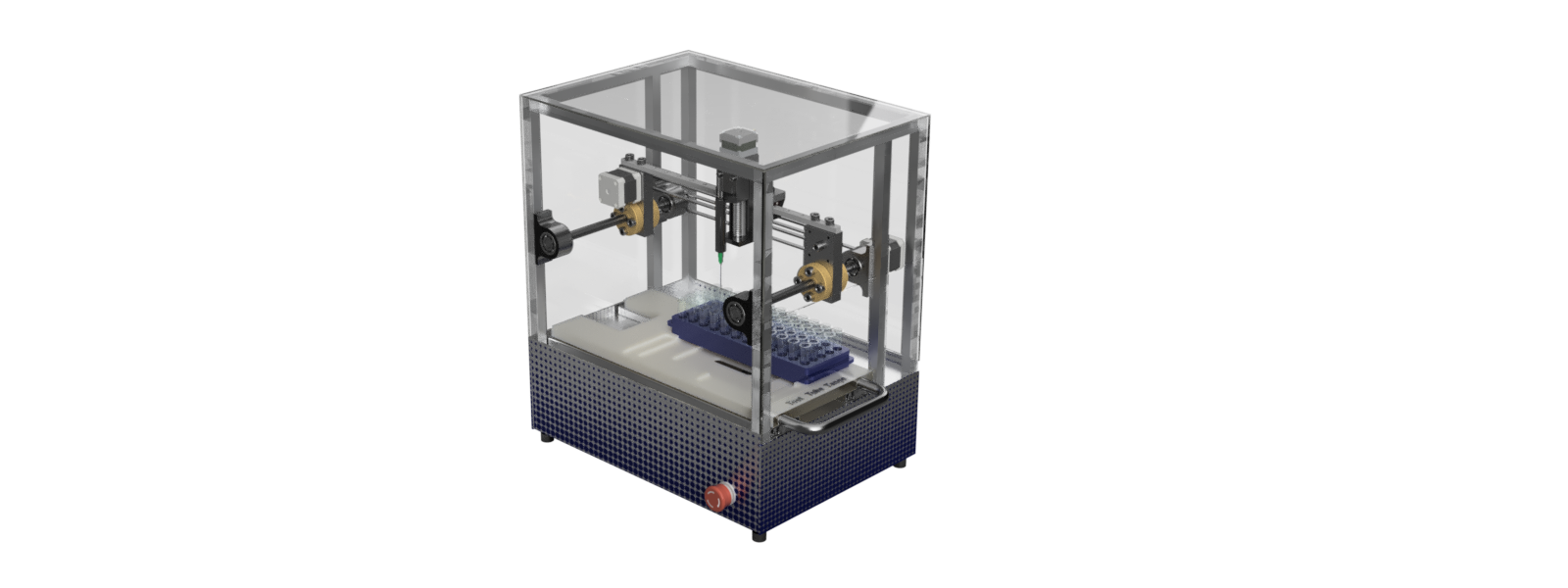

The Test-Tube Tango autosampler provides an affordable, compact, and efficient solution for high-throughput biofluid analysis, tailored to meet the needs of research labs and clinics operating under budgetary and spatial constraints. Developed in collaboration with Dr. Pan, the design addresses the high cost and limited adaptability of commercial autosamplers, which often exceed $10,000. Our device meets stringent specifications with a total production budget under $5,000.

The design integrates a temperature-controlled storage compartment and a CNC-style sampling and distribution apparatus. The storage compartment accommodates over 100 1.5 mL vials, 20 15 mL tubes, or 2 full 96-well plates while maintaining temperatures between 4°C and 37°C with less than 2°C variation. The sampling mechanism employs precise guided motion to extract volumes from 0.5 to 50 microliters with accuracy exceeding 99.5%. To prevent cross-contamination, an automated cleaning system flushes all lines after each operation, achieving a sampling and cleaning cycle in under one minute. Key features include Peltier modules for precise thermal control, a forced convection system for even temperature distribution, and a digital interface for user-friendly workflow management and real-time monitoring. The compact footprint (14” x 10” x 16”) ensures compatibility with space-constrained labs, while modular components simplify maintenance and allow for future upgrades.

By integrating precision sampling, effective thermal regulation, and efficient cleaning in a cost-conscious design, the Test-Tube Tango offers a practical and reliable alternative to expensive commercial systems. Its intuitive interface, safety mechanisms, and adaptable architecture make it a valuable tool for advancing laboratory automation and meeting diverse research demands.

3D Interactive Product Model

The following is an interactive 3D model of the product design. You can view and rotate the product assembly in different orientations and views, including an exploded view to see the various parts that make up the assembly.