Team Members

Douglas De Sousa, Eliana Gosiker, Elle Norstrom, Fabio Savino Rosenberg, Justin Taylor, Sayeed Ali, Travis Birdsall

Abstract

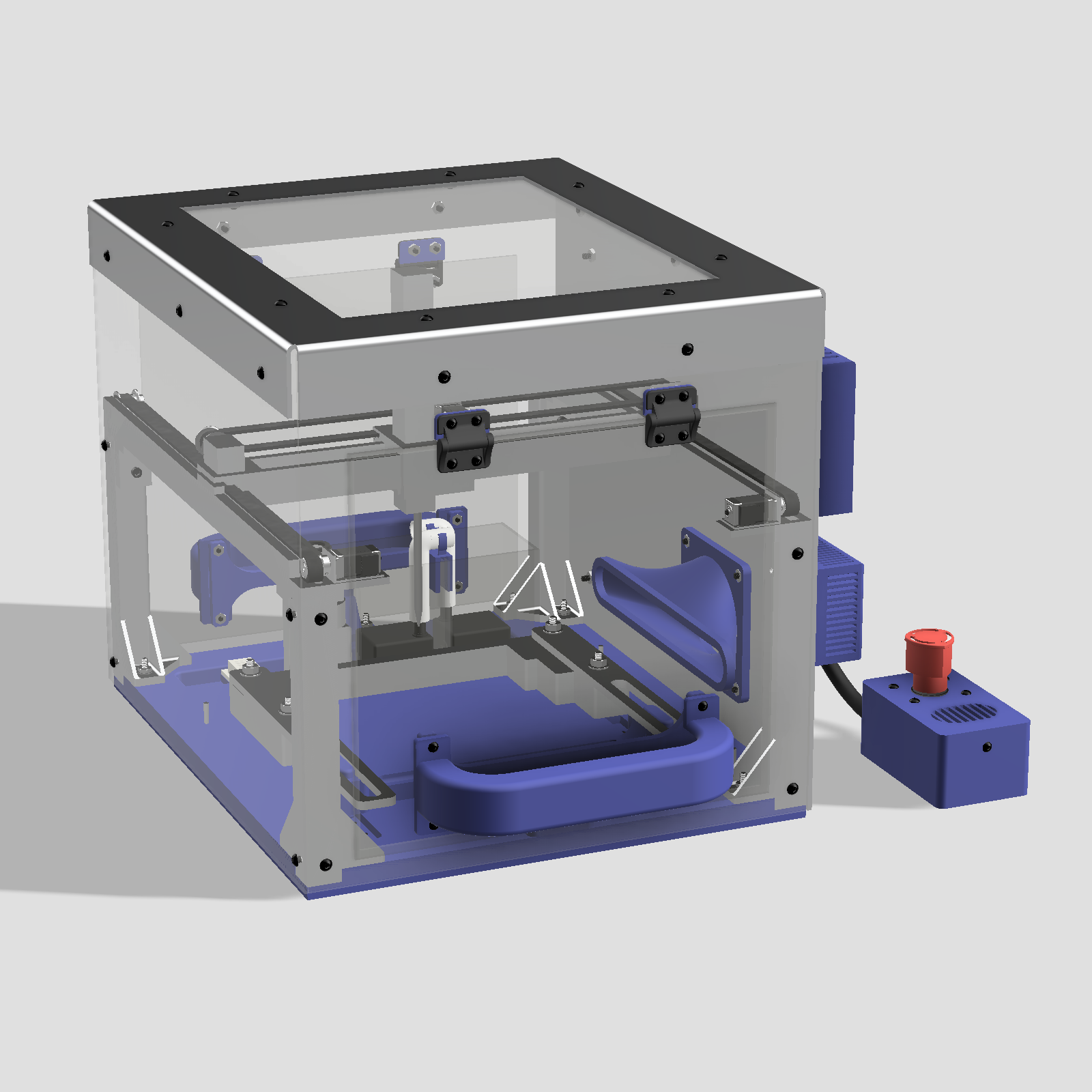

S4U was tasked with creating an autosampler that is fast, small, and relatively low-cost. This product had to satisfy the client’s unique requirements while being competitive within the general market. S4U’s autosampler, the Solution Vault Autosampler, has four main physical subsystems: Cleaning, Case Structure, Armature: Motion/Suction, and Heating/Cooling. The Cleaning System has two acrylic water cups, two water pumps, PVC tubing, and a tube mount. During cleaning, the syringe needle dips into the water and gets splashed by a pump, cleaning its exterior. The syringe pulls in water from the cup and pushes it through the MFD, cleaning its interior and the MFD. The Case Structure encapsulates all autosampler components and has a plastic base, acrylic walls and ceiling, and one aluminum column at each corner to support the armature. It has two large doors with friction hinges, and it can constrain tube holders of varying sizes that easily slide into place. Armature: Motion is made up of machined aluminum bars and a series of stepper motors, gears, and belts, which create motion in the x-, y-, and z-axes. It brings the syringe to each sample, allowing for sampling in under 1 minute. Armature: Suction is located within the z-axis bar and contains a syringe, plunger mechanism, stepper motor, and micro stepper. It provides sampling capabilities of 0.5-500 µL, with < 20% variation at the lower bound and < 0.5% variation at the upper bound. The Heating/Cooling subsystem utilizes a Peltier device along with a fan to create convective heat transfer and a diffuser to evenly heat/cool all samples. Temperature is selected on the computer UI, monitored via thermocouple, and regulated by a TEC controller. The samples can be held between 4° and 37° Celsius, ± 2°. If these bounds are exceeded, a piezo buzzer sounds.

3D Interactive Product Model

The following is an interactive 3D model of the product design. You can view and rotate the product assembly in different orientations and views, including an exploded view to see the various parts that make up the assembly.