Team Members

Alice Chen, Ash Mooney, Eric Steyn, Gabirel Pascual, Grace Vick, Kayla Raya, Stefan Kluivers, Will MacGuire

Abstract

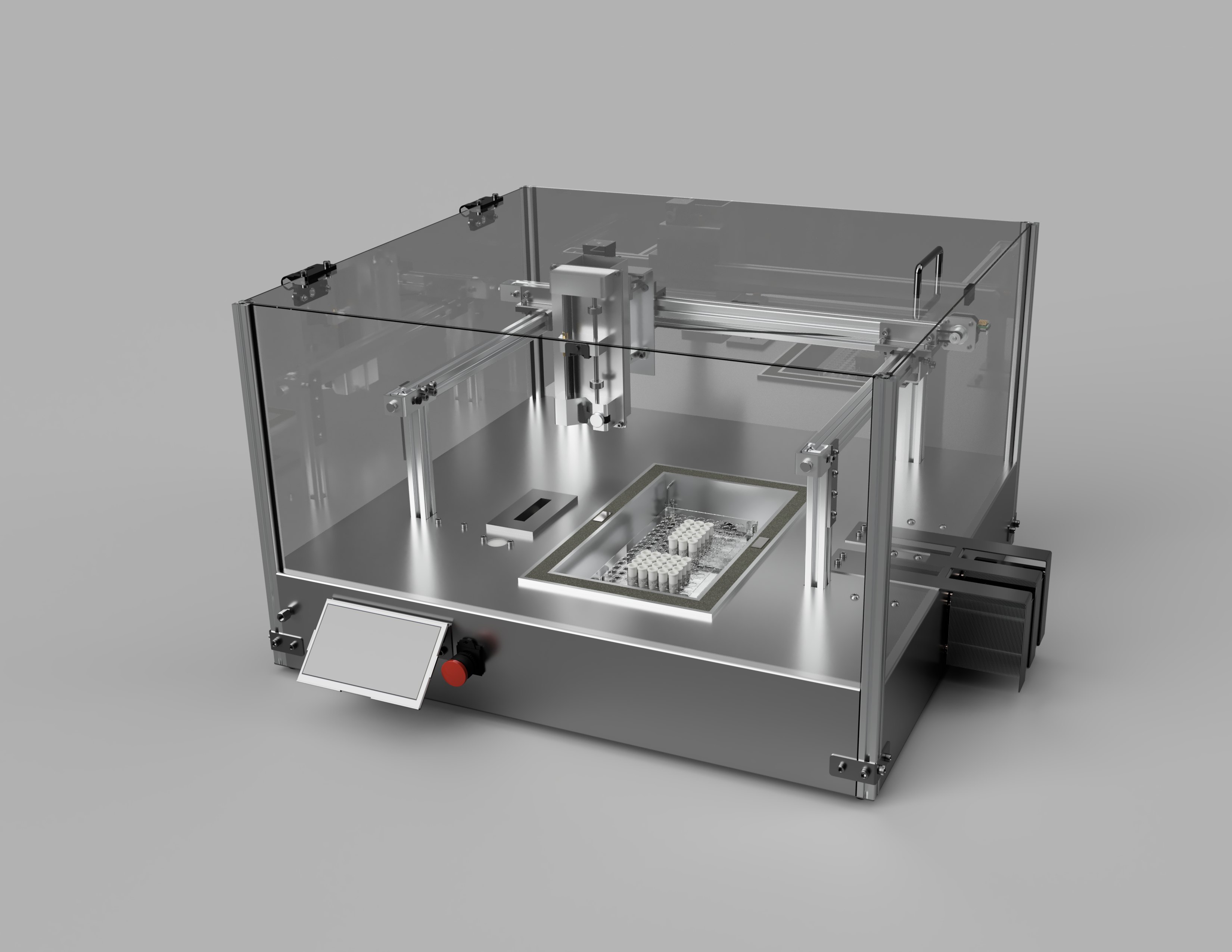

The goal of this project was to design an open-source, affordable autosampler. It must be able to store and control the temperature of many samples, be capable of cleaning the sampling mechanism and any lines than come in contact with samples, complete a sampling and cleaning cycle in under 1 minute, have an interface for a user to control the sampling procedure, have a housing and emergency stop for user safety, and be powered by a standard American 120 VAC outlet. The final device is comprised of four subsystems. The electrical subsystem consists of all electrical components, including controls for the other subsystems and a user interface where users input sampling settings and control sampling procedures. The motion and structural subsystem consist of the housing around the autosampler and the sampling mechanism, which carries the syringe pump using 3D printer-like motion with stepper motors, bearings, and a sturdy frame. The heating and cooling subsystem includes the storage box where the samples are housed and the heating and cooling units that control the sample temperature by heating or cooling air in ducts attached to the storage and using fans to run the heated/cooled air over the samples. The injection port and cleaning subsystem is a combination of two subsystems. The injection port seals around the needle as the syringe pump pushes the fluid through the line that connects to the analytical device. The cleaning trough uses running water to clean the inside and outside of the syringe and supplies water for the sampling mechanism to use to flush the injection port and its lines for the next sampling cycle.

3D Interactive Product Model

The following is an interactive 3D model of the product design. You can view and rotate the product assembly in different orientations and views, including an exploded view to see the various parts that make up the assembly.