Team Members

Adrian Costa, Carson Baker, John Plunkett, Jonathan Klepper, Kaleb Kunkle, Karen Suros, Layton Kounlavong, Riley Gilman, Zachary Beer

Abstract

In recent years, the demand for efficient biofluid sample processing has surged, driven by advancements in chemical analysis, global health challenges, and medical technology. However, many autosamplers are either too expensive for smaller labs or fail to meet performance expectations. To address this gap, our team developed an affordable, open-source biofluid autosampler that balances cost and high laboratory performance. Our device integrates four interconnected subsystems—mechanical, fluid, thermal, and electrical—to store, manage, and transport samples for analysis. Key features include an XYZ gantry with stepper motors for precise pipette movement, a temperature-regulated storage compartment, and a peristaltic pump with an inline bubble trap for smooth fluid handling. Powered by an Arduino Mega 2650 microcontroller, the system ensures reliable operation, while Peltier coolers maintain temperatures within a 2°C range. A user-friendly graphical interface allows for easy configuration of temperature, sample arrangement, and procedures. Designed for versatility, the modular system accommodates various vial types, including 96-well plates and 1.5-mL and 15-mL vials, while built-in cleaning mechanisms minimize cross-contamination. By leveraging cost-efficient materials like 3D-printed PLA and plexiglass, we kept prototype costs under $3,000, making high-throughput sampling more accessible to labs of all sizes. This project is more than a technical achievement—it’s a step toward making lab tools more accessible and empowering smaller labs to contribute to critical medical research and improved diagnostics. Developed for our client, Dr. Jing Pan, this autosampler has the potential to transform research and healthcare, and we’re excited about its future impact.

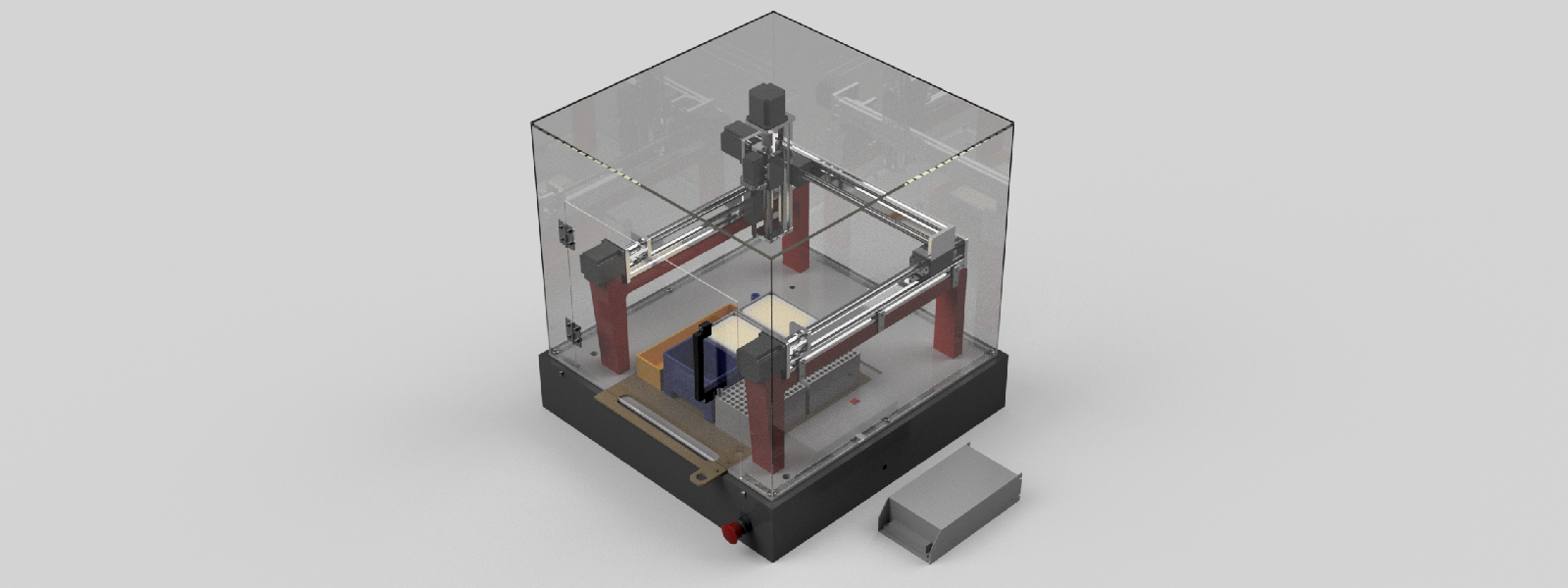

3D Interactive Product Model

The following is an interactive 3D model of the product design. You can view and rotate the product assembly in different orientations and views, including an exploded view to see the various parts that make up the assembly.