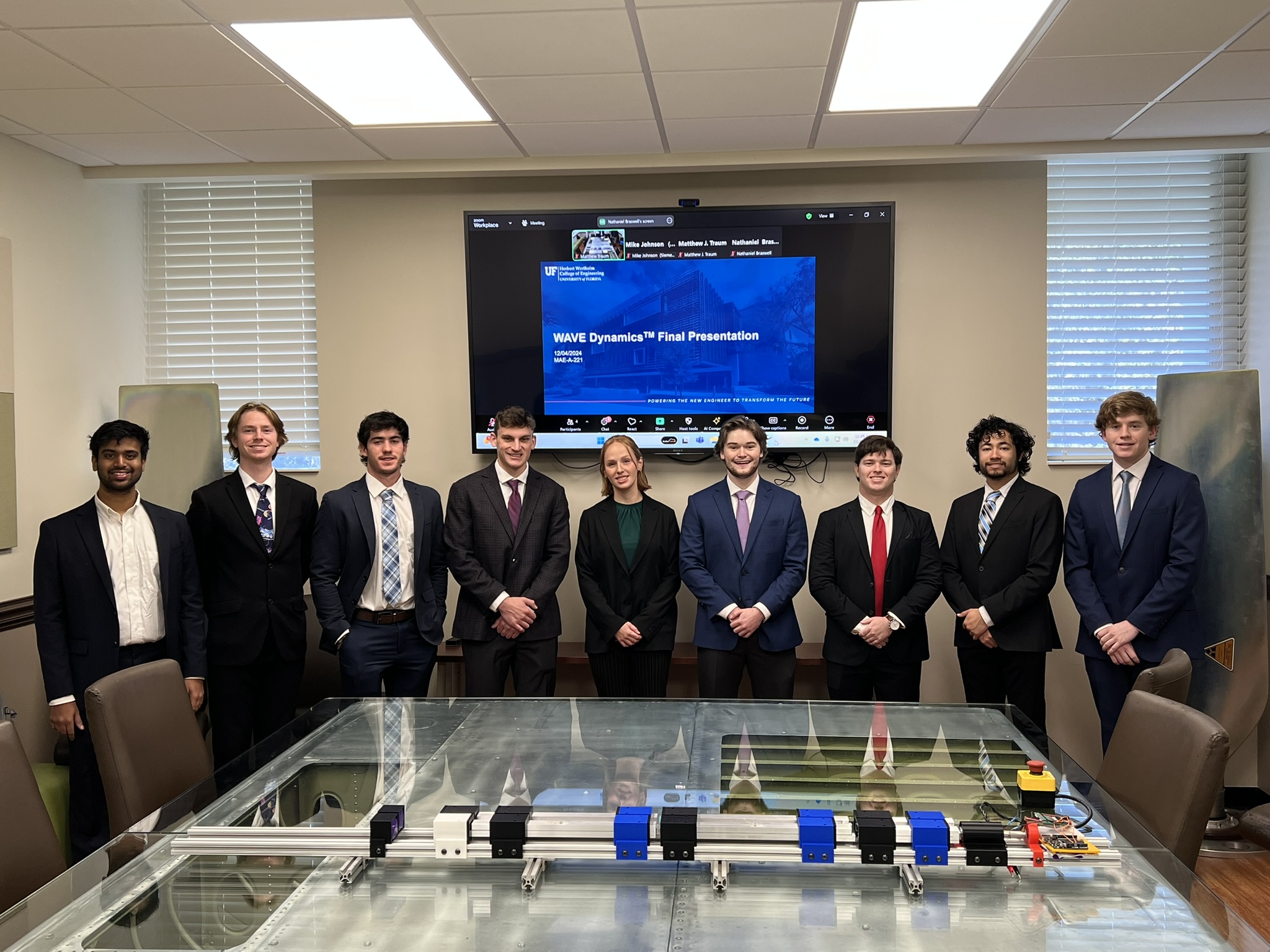

Team Members

Hannah Baradon, Nathaniel Braswell, Eduardo Mora, Zachary Bradley, Zachary Hibshman, Julian Trerotola, Ronan Duffy, Samuel Mariash, Sanjeev Radhakrishnan

Abstract

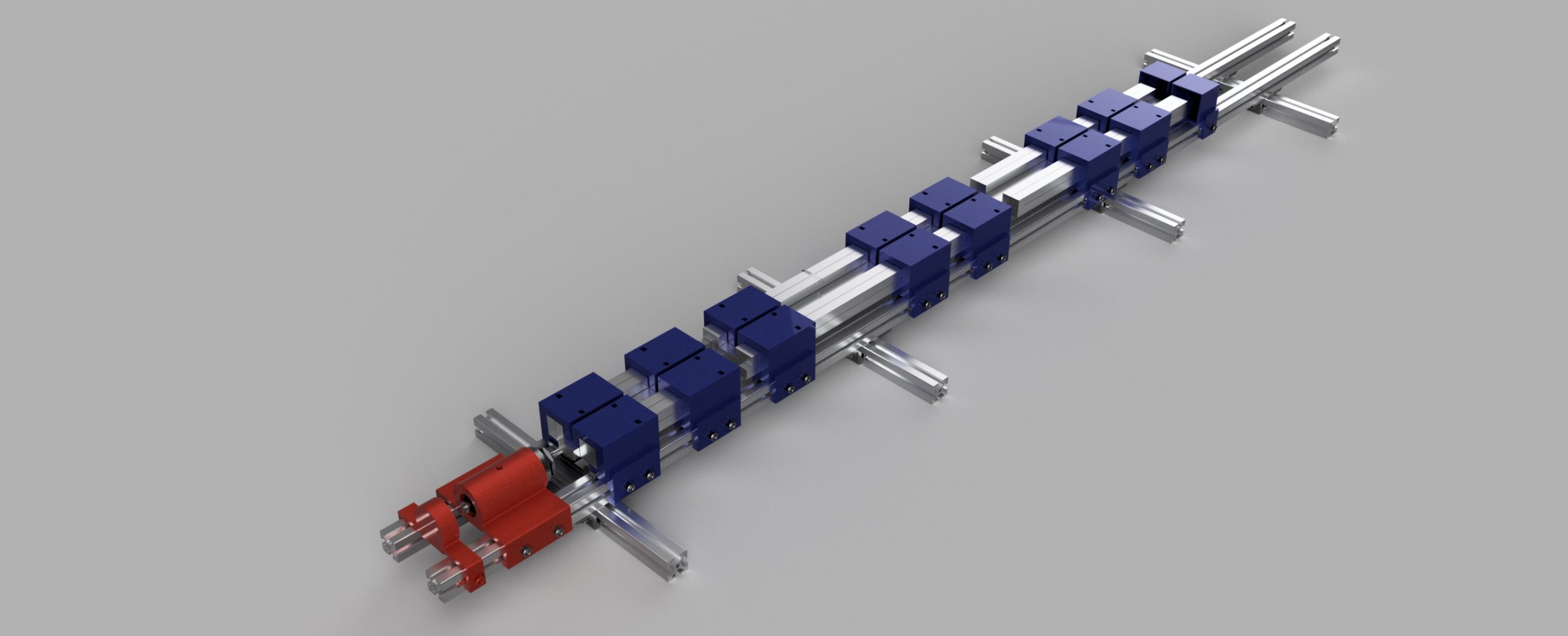

Wave Dynamics delivered an innovative and low-cost design solution for the millipede bar test system design problem. The design solution is a nuanced, compact version of the famous Split Hopkinson Pressure Bar that allows for medium strain rate dynamic material testing. The test system meets the most critical design objectives by prioritizing the ability to test wave propagation through the millipede bar geometry. The stress wave is induced in the test system by using a high force push solenoid that is electrically actuated which impacts the striker bar. The millipede bars themselves are the highlight of the design, using precise CNC milling from a manufacturing on demand company. The 3 millipede bars in the assembly: the striker bar, incident bar, and transmission bar, are all manufactured precisely to make sure the contact surfaces are completely flat to each other. Fixed boundary conditions at the millipede bar bend junctions are implemented using custom designed 3D printed clamps with metal ball bearing balls. The clamps are also utilized to ensure smooth 1D axial motion of the millipede bars by restricting their motion in all other degrees of freedom. This design succeeds in testing the cutting-edge theory of wave propagation and serves as a new option for lower budget institutions to pursue novel research in the field of dynamic materials testing.

Pitch Video

3D Interactive Product Model

The following is an interactive 3D model of the product design. You can view and rotate the product assembly in different orientations and views, including an exploded view to see the various parts that make up the assembly.