Team Members

Leilani Lyons, Eli Fernandez, Luke Braun, Dylan Leyva, Ashley Burke, Tiffany Cheng, Makayla Hastie, Owen Chong

Abstract

The advancement of technology has fostered the increase of thermal imaging in military operations, subsequently reducing the effectiveness of traditional physical decoys. Infrared camera systems detect heat signatures of military vehicles by capturing their thermal energy, revealing the operational state of the vehicles. To address this issue, our team developed a thermal decoy capable of emulating the thermal signature of a M2A4 Bradley Infantry Fighting Vehicle (IFV). The objective of the design is to deceive enemy thermal imaging systems to divert threats away from real military vehicles. Utilizing the Double Diamond Design Process, our team completed the Discover, Define, Develop, and Deliver phases to arrive at an effective solution while remaining in the client's constraints, including but not limited to a $10,000 budget and a 30-minute field assembly. The final design consists of four key subsystems: a fiberglass rod frame that replicates the shape and dimensions of a Bradley IFV; a polyester tarp with varying ceramic fiber insulation thickness to replicate the vehicle's gradient heat signature; a heating system that utilizes a furnace to intake air and supply heated air to the area within the tarp; and a power and fuel system using a 3 kW generator and a 20-gallon propane tank for 24-hour operation. The thermal decoy design mimics the thermal energy produced by a Bradley IFV through a combination of a high emissivity polyester tarp as well as varying surface temperatures achieved through varying levels of insulation. The solution not only meets the client's design requirements but can additionally be repeated for alternative military vehicles for future applications; therefore, the thermal decoy discussed in the report provides an effective solution for the client.

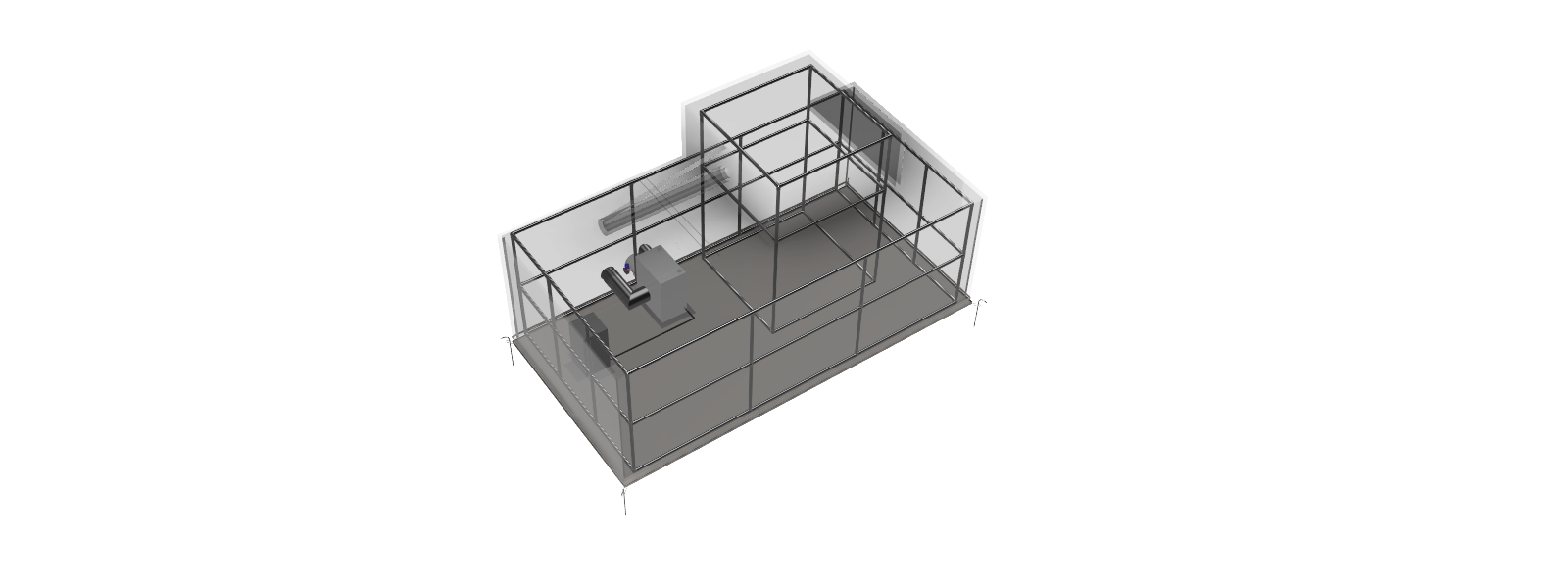

3D Interactive Product Model

The following is an interactive 3D model of the product design. You can view and rotate the product assembly in different orientations and views, including an exploded view to see the various parts that make up the assembly.