Team Members

Sasha Gorbanovski, Juan Orjuela, Ryan Wiener, Trent Walker, Thomas Rice, Stephanie Norman, Robert Kaufman, Ariana Hasan, Matthew Burns, Connor Annett

Abstract

Recycling wasted 3D filament, whether in the form of support material or failed prints, has become an important endeavor in making 3D printing more affordable and environmentally sustainable. Yet traditional equipment meant to accomplish this is often unduly large and expensive, placing a heavy burden on small startups and individuals looking to capitalize on this technology. GreenGrind Systems™ has developed separate but modular grinder and pelletizer systems that are designed to solve these issues for two key steps of the 3D filament recycling process. Our products are more affordable and versatile than any other commercially available product and are designed to handle any potential input within their specified size ranges. Our grinder's tough, durable two-stage grinding mechanism is designed to handle print infills up to 100%, ensuring that any waste can be processed for recycling. Additionally, our advanced sorting mechanism uses compact vibration motors that sift the grinded pieces through a two-stage mesh, ensuring that our system's output is at an optimum size for future recycling processes. Any oversized pieces can easily be reprocessed by our grinder using a simple and user-friendly hopper assembly. Our pelletizer system also embodies our customer commitments, with features such as: a significantly reduced footprint compared to our competitors, a low production cost due to the judicious use of reliable COTS parts, and a versatile pellet production mechanism that can handle a wide range of filament diameters. Overall, our products will provide better access to easier, cheaper, and more efficient 3D print waste recycling.

Pitch Video

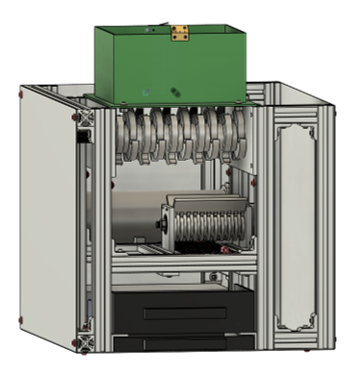

3D Interactive Product Model

The following is an interactive 3D model of the product design. You can view and rotate the product assembly in different orientations and views, including an exploded view to see the various parts that make up the assembly.