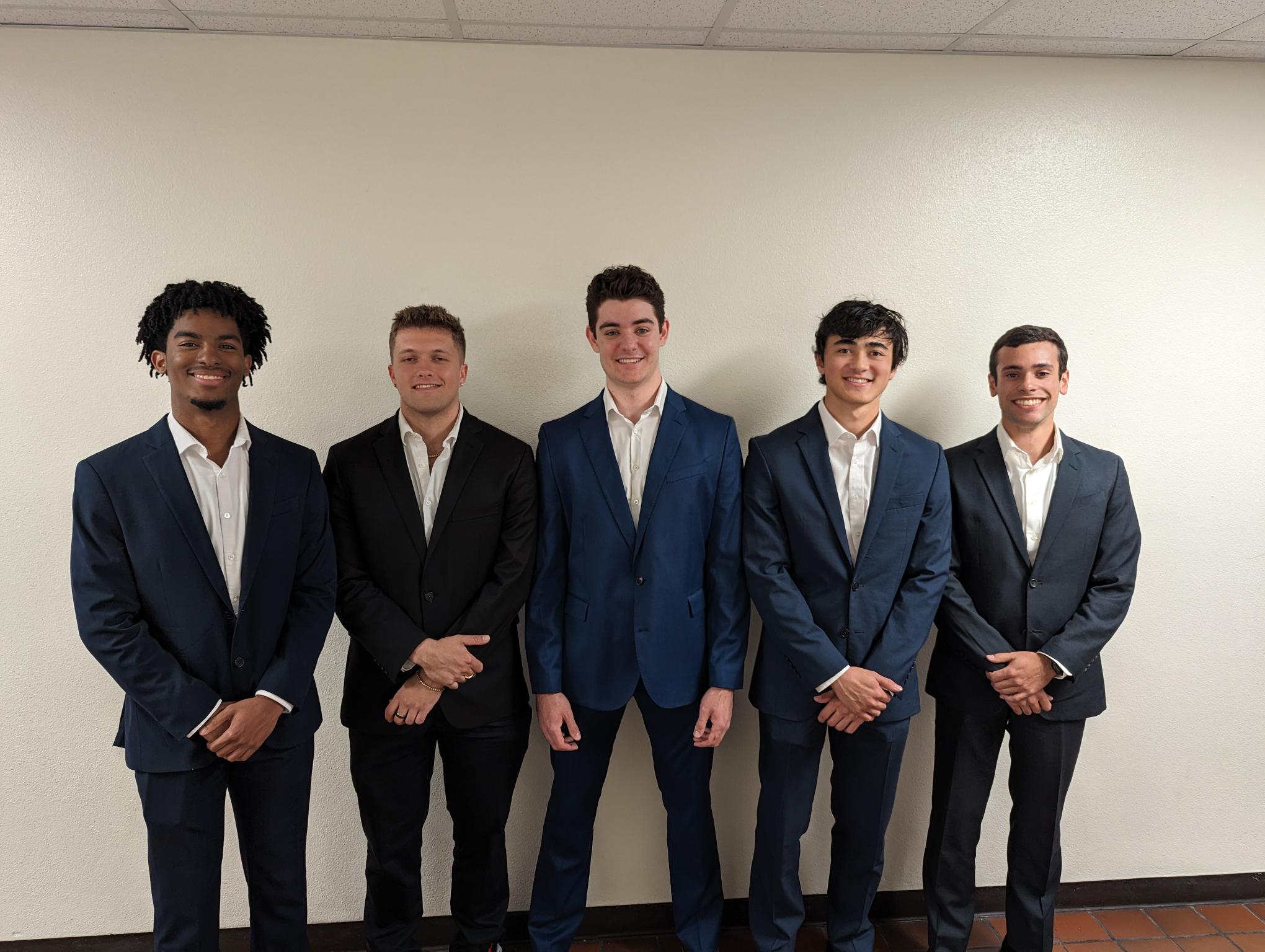

Team Members

Mason McCord, Jamar Ivey, Nicholas Sardinia, Ryan Wiener, and Raymond Millero

Abstract

The University of Florida (UF) has requested our expertise to design a docking system that can mate two crafts together in deep space to function as one spacecraft. As a part of the university’s ever-growing development in the space industry, a plan has been set in motion to send CubeSats to the Earth-Sun Lagrangian points L1 and L5 to study the solar activity’s impact on space weather near Earth. The L1 point is 1.5 million kilometers from the Earth, and the L5 point is 149 million kilometers from the Earth. These CubeSats are to remain in space for at least a year studying the space environment. To conserve fuel during the trips between the L1 and L5 points and keeping the satellites positioned and oriented, it was determined that two CubeSats would be docked together. A science instrument module and a propulsion module. The proposed design makes use of OTS parts to control active components. Additionally, custom machined parts were made to fit material stock sizes to minimize material waste and lower production cost. The design comprises of 5 subsystems: base plate, active capture mechanism, linear pin actuation, fuel transfer system, data/power transfer system. As the CubeSats are soft docking the propulsion module’s conical protrusions align and mate with the science module’s countersink geometry. Then the active capture mechanism will sprout arms from the science module to pull the two crafts together. Once properly mated the linear actuator will push a pin through the mated conical tuna cans and rigidly lock the spacecrafts together. Simultaneously, the fuel transfer system and power/data transfer system make secure connections once the crafts have fully docked. This design is unique because of its active capture mechanism which guarantees a secure mating of the two spacecrafts.

Pitch Video

3D Interactive Product Model

The following is an interactive 3D model of the product design. You can view and rotate the product assembly in different orientations and views, including an exploded view to see the various parts that make up the assembly.