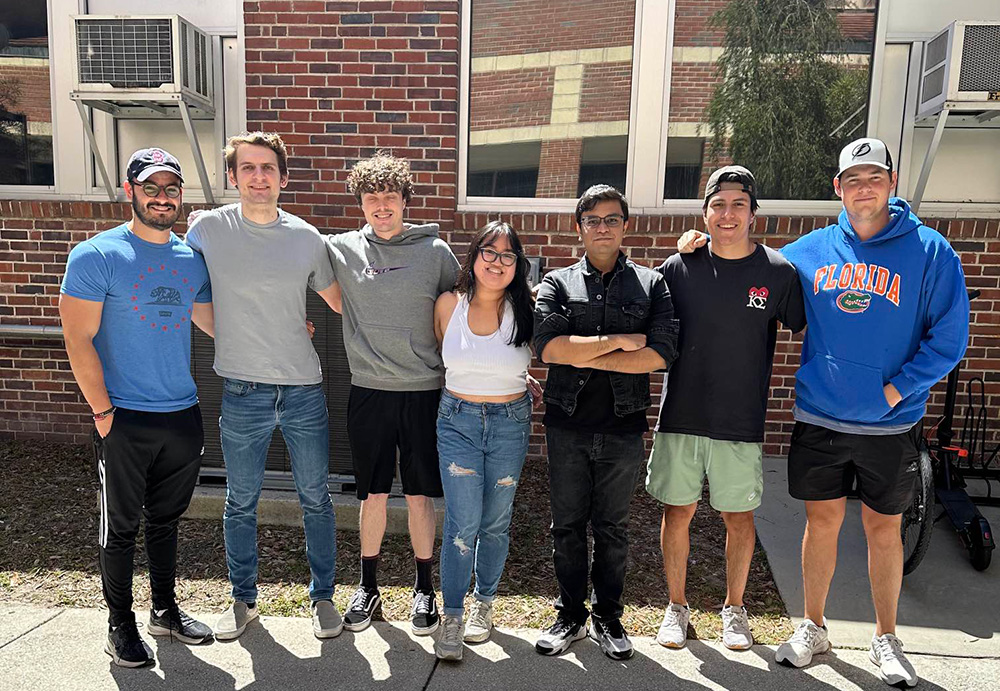

Team Members

Alex Lugo, Caitlyn Limpioso, Joshua Kempfert, Marco Moreno, Orlando Travers, Samuel Fetter, Raian Sadman

Abstract

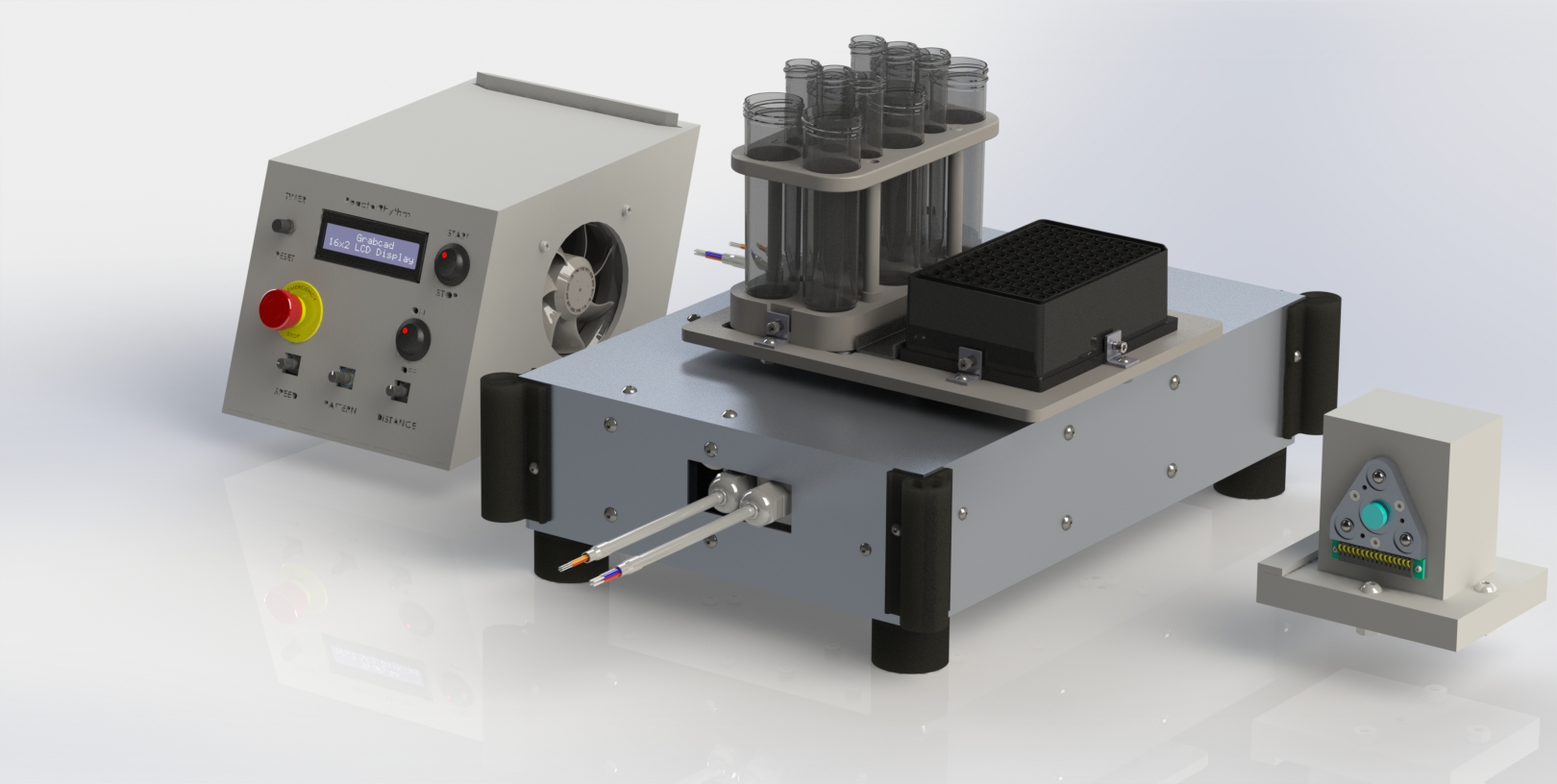

The goal of our design was to incorporate an easy-to-use user interface system, optimize the design, and powerfully drive a shaker table system. Our system is capable of operating at over 1000 rpms, which is accomplished using a dual-belt pulley system, driven by two stepper motors. The stepper motors are IP65 rated and implement encoders to ensure positional accuracy. Our high-power stepper motors and custom rail system are essential contributions to our power capability and are what differentiates us from competition. The HDPE body is mounted to the top of our shaking mechanism and supports six 15 mL and six 50 mL test tubes. In addition, there is an incorporated enclosure fabricated from sheet metal with rubber bumpers and feet to dampen falls and reduce vibrational movement. Our User Interface is a 3D printed PETG shell with an LCD display, which allows for mechanical control of parameters such as speed, distance, and pattern. Finally, for our OD/FI system, we have built-in LEDs secured under the well plate and tube racks that illuminate selected solutions on-command. Our sensor package is positioned to sense the optical density and fluorescent intensity of selected solutions via a robot arm.

Pitch Video

3D Interactive Product Model

The following is an interactive 3D model of the product design. You can view and rotate the product assembly in different orientations and views, including an exploded view to see the various parts that make up the assembly.