Team Members

Anthony Alcin, Richard Berrios, Stanley Noel, Niraj Patel, Shayne Pollock, Jessie Shutzberg, Sam Thomasson

Abstract

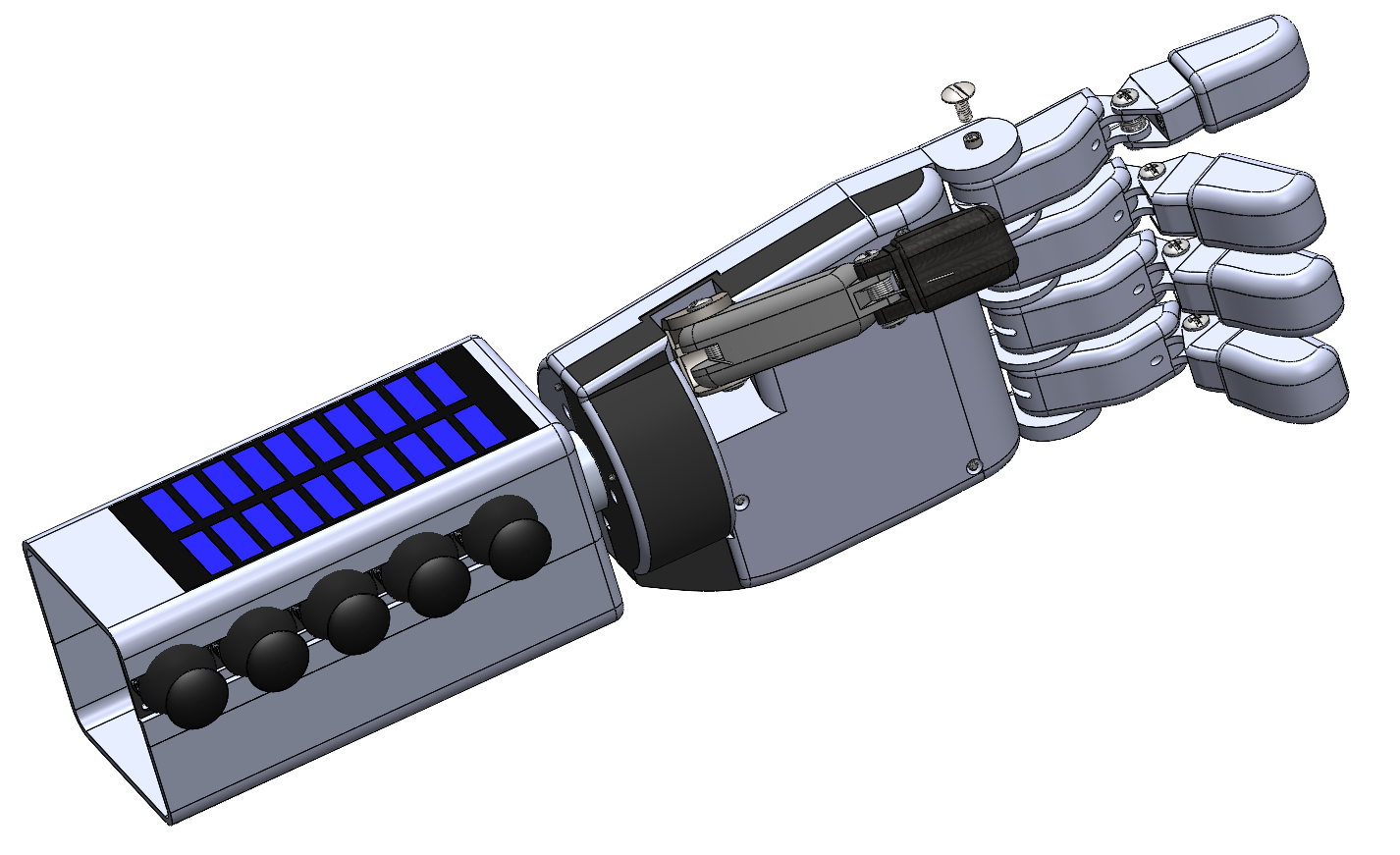

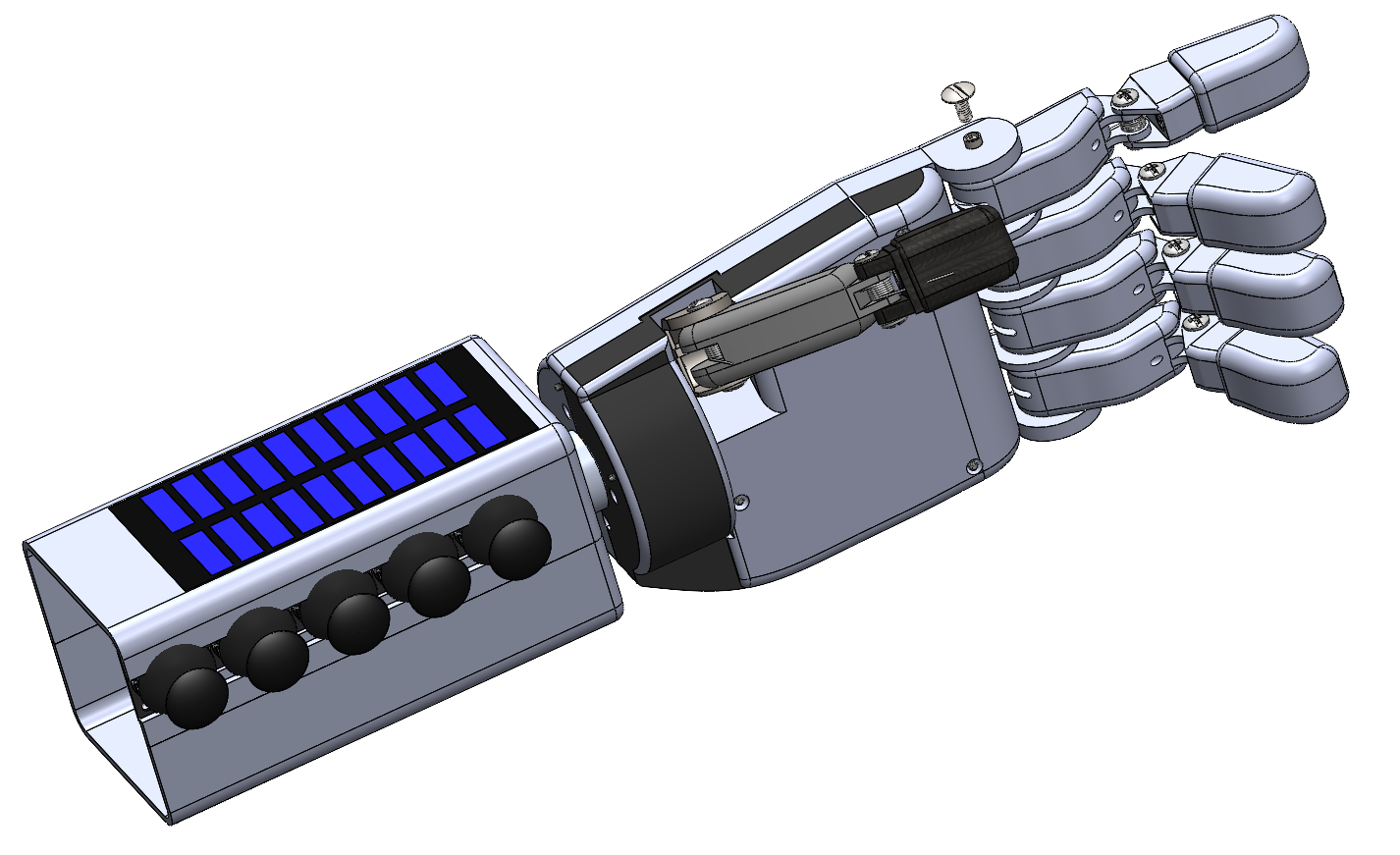

Our device was designed to be an economically maintainable, structurally intricate, and fully modular rapid prototyped prosthetic arm. The product is equipped with joystick controls to allow for individual finger actuation, which allows users to make specific hand signals and grasp all kinds of objects. The electrical circuit was soldered in a perfboard and mounted within the forearm, connecting the linear actuators in the hand through the wrist tube and the user interface located on the outside of the forearm. The device is economically maintainable because the majority of our components, including the fingers, forearm, and palm of the hand are rapidly 3D printed using economically viable and worldly available ABS filament. Only the wrist tube and off-the-shelf parts were not 3D printed. We also honed our product to be fully modular, depending on the biometric preferences of the users. This allows users to quickly request longer fingers or shorter forearms and obtain the ordered parts quickly because of the fast 3D printing methods. The design is intricate with rounded edges to add to aesthetics and safety of the user. Our design provides customers with a trans-radial prosthetic arm that is rapidly manufactured, easily repaired, and intuitively controlled, which adds value to our design.

Pitch Video

3D Interactive Product Model

The following is an interactive 3D model of the product design. You can view and rotate the product assembly in different orientations and views, including an exploded view to see the various parts that make up the assembly.