Team Members

Cameron Aitchison, Uzair Alvi, Jake Bundy, Jonathan Gordon, Zain Omar, Rebecca Simonson, Thomas Vetter

Abstract

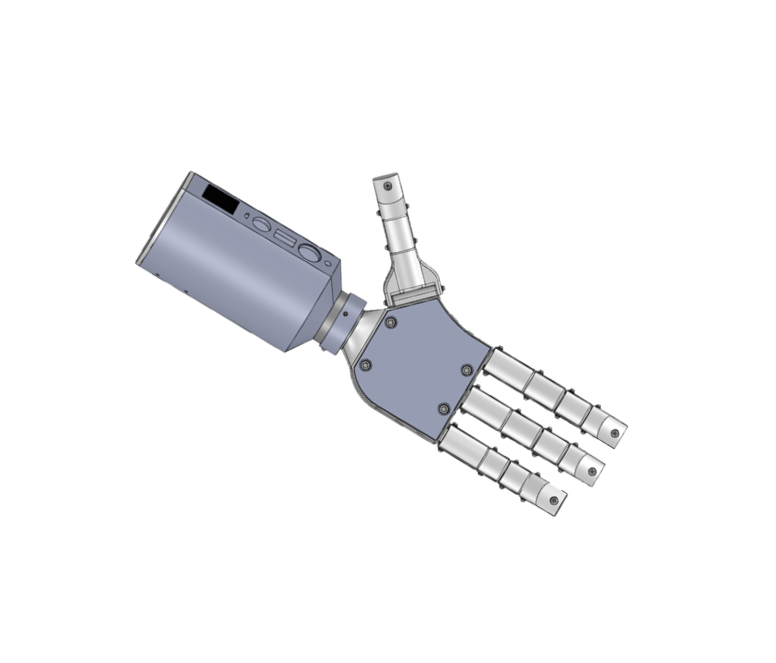

Over 3 million people around the world are living with an arm amputation, and 2.4 million of these people are in developing countries. These individuals are in need of a highly functional and cost-effective prosthesis in an effort to make life easier. LogicaLimb aims to address this need through our P.A_01 Prosthetic Arm design. The average price for a prosthetic arm is around $8,000 – $30,000 USD. Our arm is projected to be less than $300 in material cost with labor only being needed for assembly. Additionally, 3D printing allows our product to be manufactured anywhere around the world and assembled with common household items. Relying on the emerging technology of 3D Printing, LogicaLimb’s design is versatile through customization, as well as cheaper than leading competition. LogicaLimb implemented a 4-finger design for their prosthesis, to ease assembly while maximizing performance. Using DC motors acting on a string-and-pulley finger mechanism, LogicaLimb is able to maintain a lightweight yet powerful gripping force. Lithium-Ion power cells are implemented to maintain a long lasting battery life with multimodal functionality. LogicaLimb’s design and manufacturing methods make it a customizable, cost effective, and efficient prosthetic to upset the current market.

Pitch Video

3D Interactive Product Model

The following is an interactive 3D model of the product design. You can view and rotate the product assembly in different orientations and views, including an exploded view to see the various parts that make up the assembly.