Team Members

Aidan Bowman, Allen Martinez, Carlos Rios, Isabella Eby, Jonah Schulman, Justin Taylor, Kayla Bronson, Michael Corona, Nicolas Rosario, Xavier Morris

Abstract

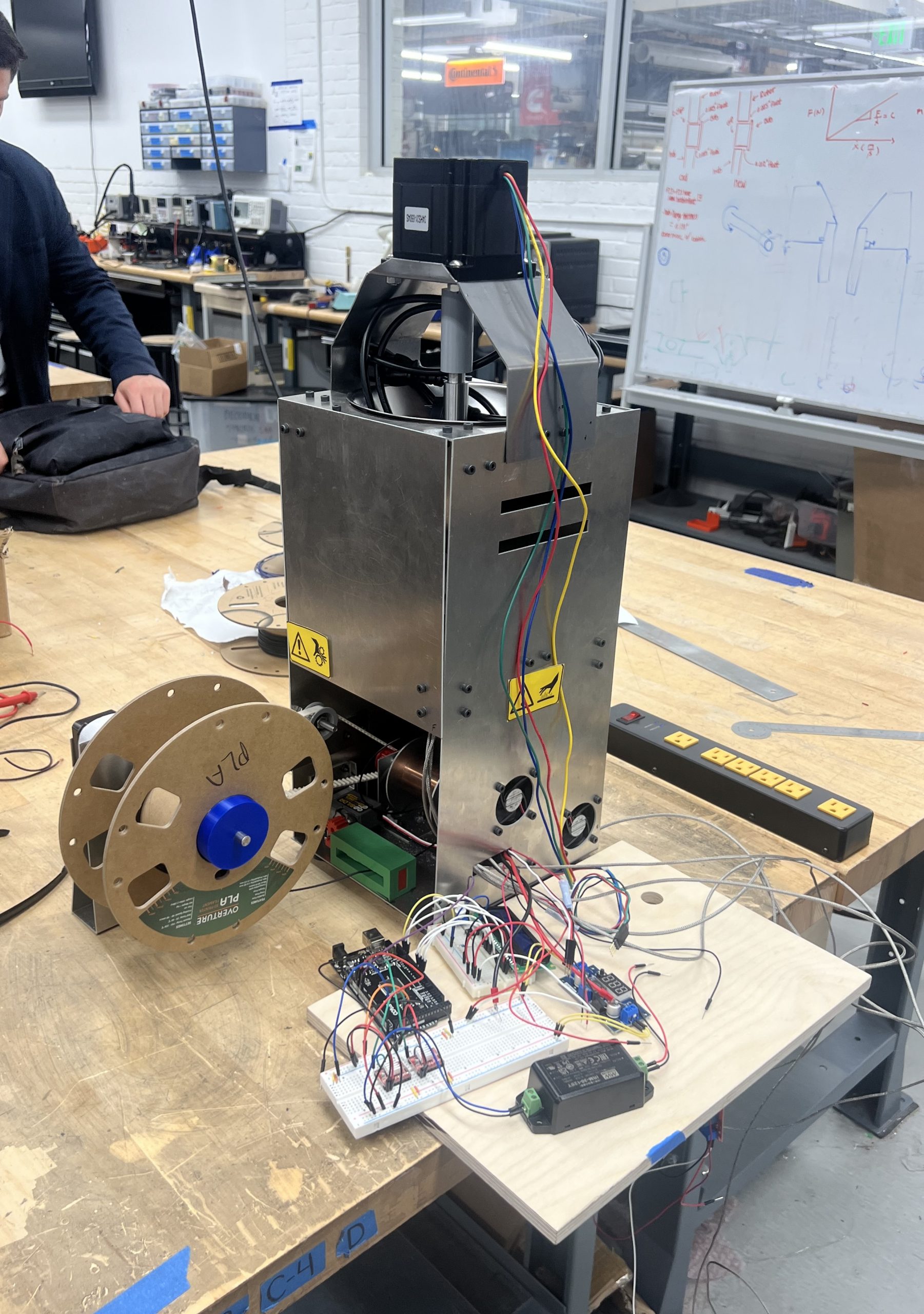

United Filament Operations (UFO) behaves according to a focused mission: to transform plastic waste into high-quality 3D printing filament through reliable, cost-effective solutions. Filament 51 contains automated extrusion, conductive cooling, and filament spooling which can be accurately repeated; therefore, UFO built the product centered on simplicity, precision, and sustainability. The key attraction to UFO's design is the innovative approach to cooling the filament after extrusion. Conductive cooling has never been utilized in filament printing before; therefore, UFO empowers innovators and manufacturers to use ground-breaking solutions that place them at the forefront of commercial filament cooling. Filament 51 utilizes a fully integrated feedback control system to maintain proper filament heating temperatures, as well as traverse winder guides that produce a clean, professional spool without user intervention. All design aspects maintain the filament at the peak of commercial standards.

Pitch Video

3D Interactive Product Model

The following is an interactive 3D model of the product design. You can view and rotate the product assembly in different orientations and views, including an exploded view to see the various parts that make up the assembly.