Team Members

Jason Algeo, Michael Carr, Patrick Dougherty, Alec Feller, Devin Haber, Melanie Herrera, Robert Hilton, Alexis Sturm, & Jake Vetter

Abstract

In pursuit of enhancing the quality of life for amputees in developing countries, our team is dedicated to creating a 3D-printed prosthetic arm that integrate artificial intelligence algorithms and myoelectric sensors to achieve a variety of functional grasp configurations. By creating a prosthetic device consisting of mostly 3D-printed parts, we can produce it at the lowest price point. A 3D-printed design allows for easy manufacturing and mass production, rather than adjusting our product’s design on a situational basis. To get our product to people who cannot afford more expensive modernized prosthetics, we will partner with local medical clinics and hospitals to supply them with an in-house 3D printer and starter filament so that each prosthetic can be manufactured locally. This approach eliminates the distribution middleman and significantly reduces the shipping and handling costs. Our design is unique from other prosthetic arms because we replaced most of our off-the-shelf parts with 3D-printed ones. We are using all 3D printed fasteners, allowing for easier manufacturability and more accessibility to internal components for single-handed users. Our design also incorporates a BOA lacing system that is commonly used in the sports industry to tighten the attachment comfortably and easily around the user’s arm. The BOA system allows for ease of use and can fit users of different residual limb sizes. Additionally, our design implements myoelectric sensors to measure electrical signals from muscle movements. With the help of AI pattern recognition and classification, these inputs are translated into one of our pre-determined grip configurations.

Pitch Video

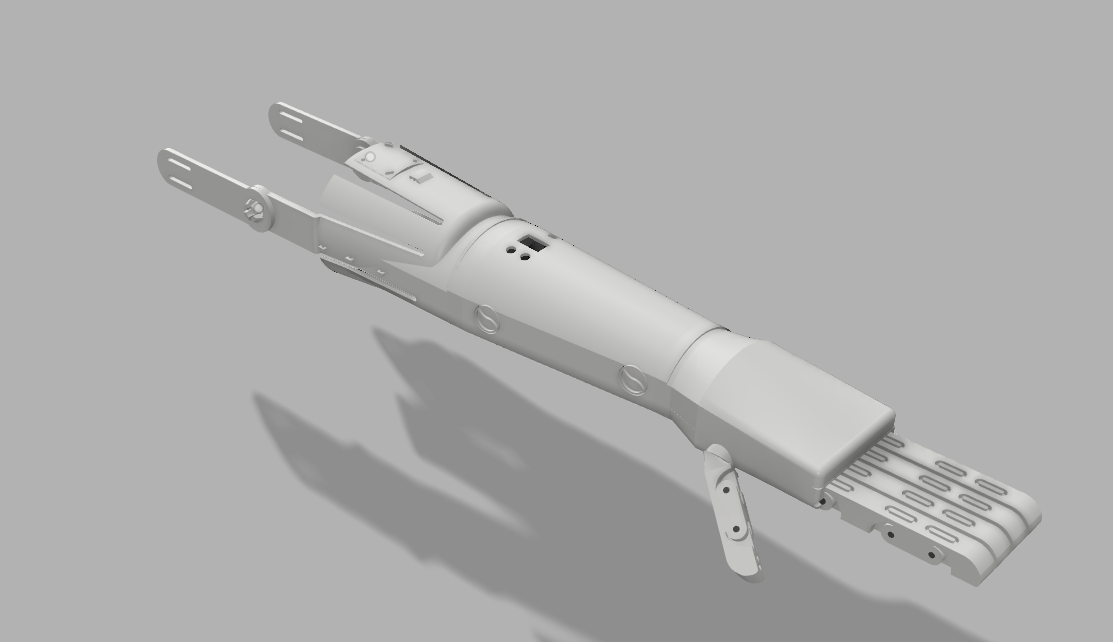

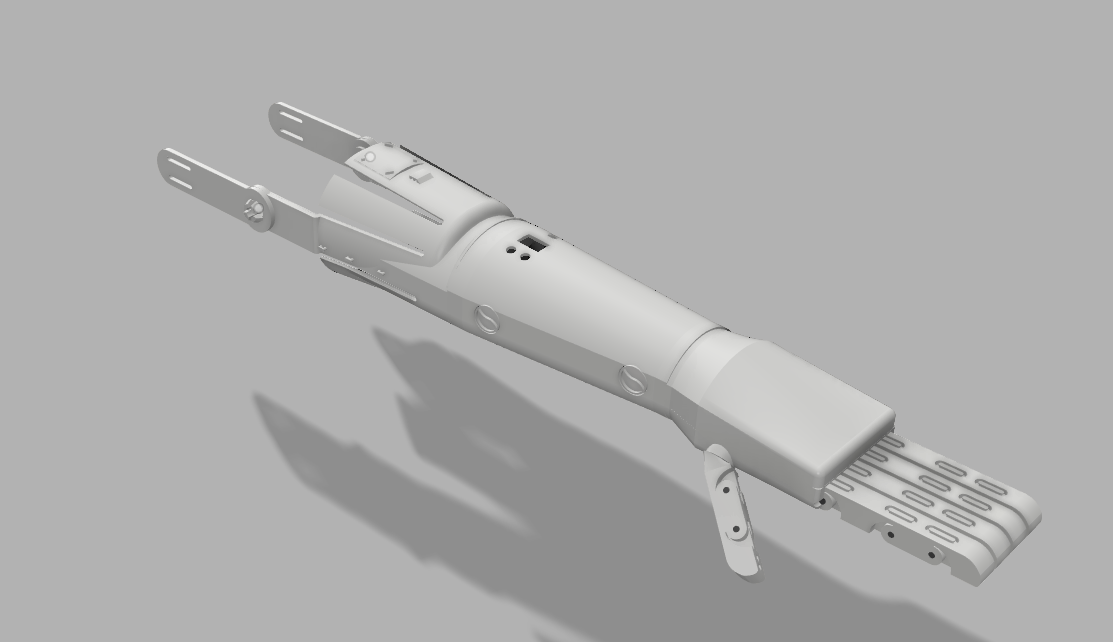

3D Interactive Product Model

The following is an interactive 3D model of the product design. You can view and rotate the product assembly in different orientations and views, including an exploded view to see the various parts that make up the assembly.