Team Members

Carson Baker, Daniel Borras-Quintero, Melissa Gonzalez Grospe, Brad Kelley, Landon Levering, Gregory Martens, Alex Martinez, Camerin Rogers, Aydan Soto, Yannick van der Laan

Abstract

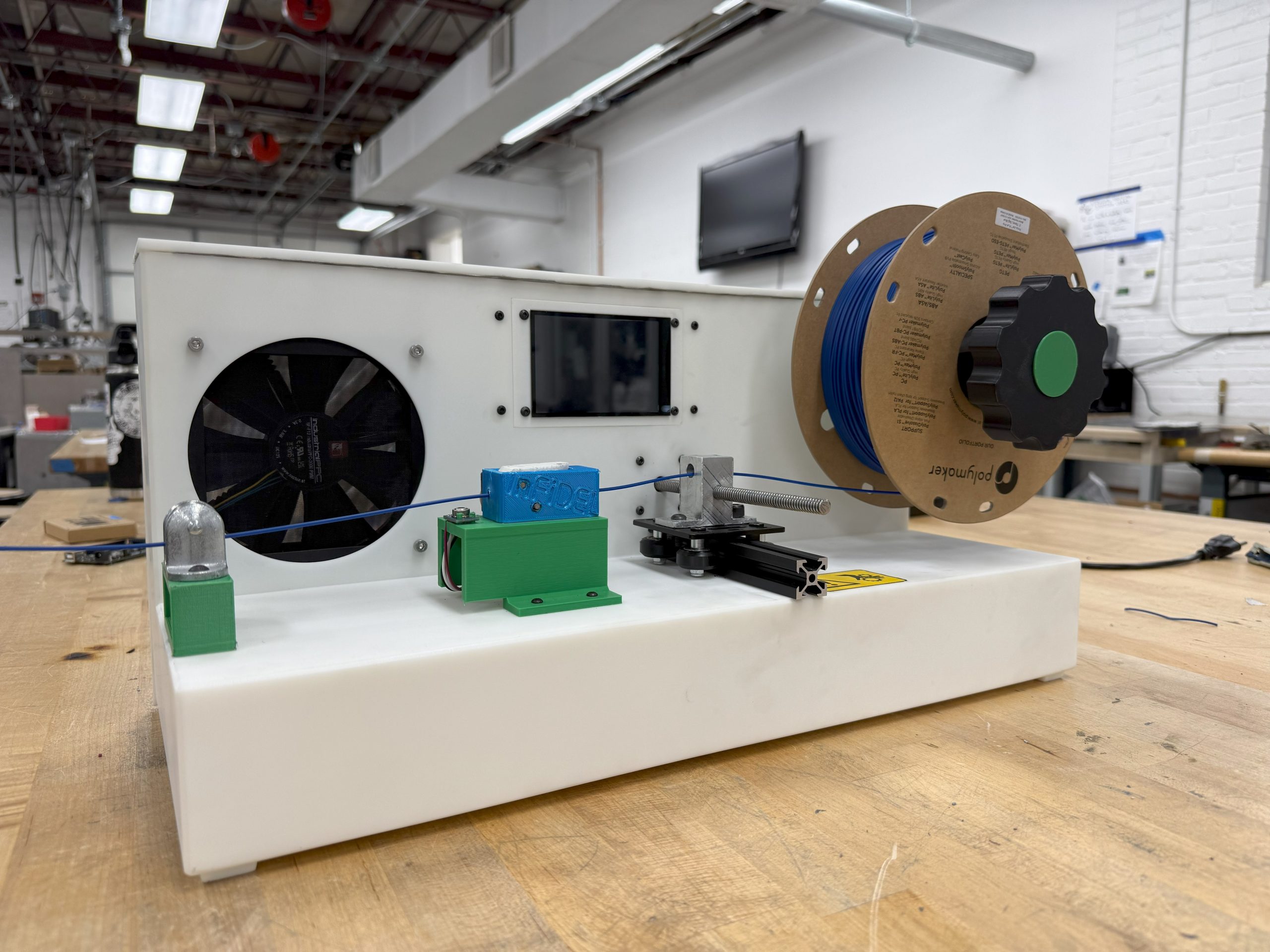

Our filament cooling, sensing, and winding system prioritizes consistent quality and long-lasting performance, ensuring sustainable high-precision filament production from recycled 3D printing waste. The SpooliganTM offers a cost-effective solution in a compact body designed to optimize the filament recycling process for both hobbyists and 3D printer farms alike. This design provides a high degree of accuracy and control, allowing the user to set their desired filament diameter to be wound onto a spool. The cooling fan and temperature sensor ensure that the diameter sensor takes measurements from a solid filament to enhance the accuracy of the measurement. A touchscreen allows the user to intuitively select their desired filament diameter and start the spooling job. The temperature, diameter, and estimated run time of the job are displayed on the screen to allow the user to monitor the job in real time. The diameter as a function of spool position is saved as a .CSV file onto a micro-SD card, which can be extracted by the user to ensure the diameter was properly regulated throughout the process. Additionally, the diameter can be monitored in real time over Wi-Fi, allowing the user to check in on the process without needing to be near the product. The Spooligan™ offers a uniquely affordable and intuitive solution for sustainable filament recycling without compromising performance.

Pitch Video

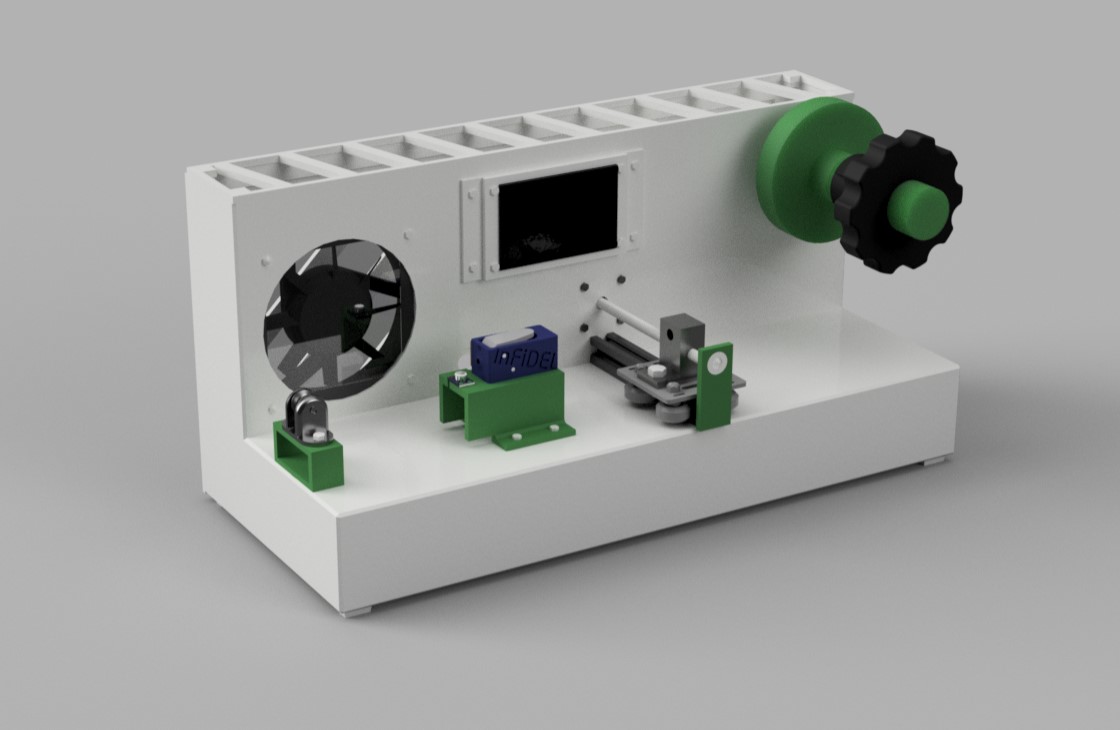

3D Interactive Product Model

The following is an interactive 3D model of the product design. You can view and rotate the product assembly in different orientations and views, including an exploded view to see the various parts that make up the assembly.